MIPR Corp will solve your food-grade conveyor belting challenges across baking and food processing applications including special profiles for dough handling, belts that are grease and oil resistant, and non-stick cut-and-gouge resistant FDA/USDA belts.

MIPR Corp carries a wide variety of thermoplastic and FABSYN belts for the various material-handling needs of the food processing industries, including full line of USDA certified belting products. You will find our staff extremely knowledgeable with more than 30 years of experience in conveyor belting applications.

Contact MIPR Corp today to discuss your needs for food-grade and FDA/USDA conveyor belting for your application. We carry a full-line of conveyor belts and belting.

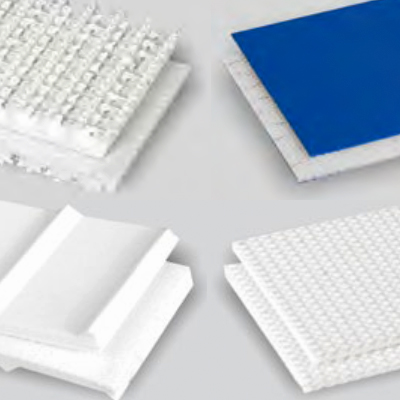

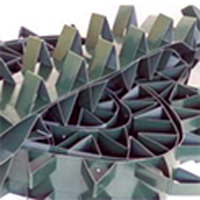

FABSYN FOOD GRADE INTEGRALLY MOLDED PROFILE & CLEATED BELTS

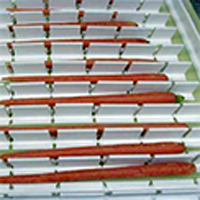

Food Grade FABSYN Cleated Belts – MIPR Corp’s FABSYN FDA approved food belts are conveniently stocked in five standard specifications. Two working tensions are available. (1) FABSYN 100, integrally molded 1 1/2″ or 2 1/2″ molded cleats. 3/8″ thick, on 6″ or 12″ centers: and (2) FABSYN 150, with either 1 1/2″ or 2 1/2″ molded cleats. 3/8″ thick, on 6″ or 12″ centers. The 150 also is offered with a 3″ cleat, 1/2″ thick, on 12″ centers. Cover, cleats and belt are molded in one operation. 48″ wide and cut to desired widths. Fabsyn cleated belts are manufactured with synthetic fabric and oil-resistant covers. Temperature range is 0° to 220° F.

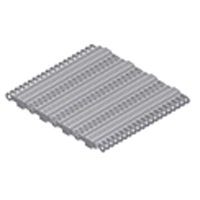

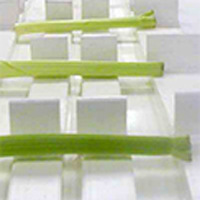

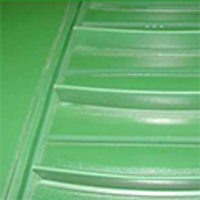

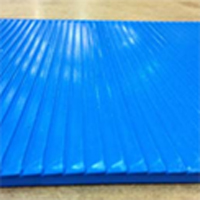

Food Grade FABSYN Profile Belts – MIPR Corp’s FABSYN profile belts are molded and cured in one operation. Four patterns are available for immediate shipment. These include: (1) the CORRUGATED pattern, rounded ribs 1/16″ high, on 1/4″ spacing, center to center; (2) the ASENDOR pattern, ribs 1/8″ high on 1″ spacing, designed for incline conveying of small and medium sized food products: (3) the TOP FLIGHT pattern, lateral cleats 3/16″ high on 6″ centers, and longitudinal cleats 3/16″ high on 4″ centers; raised buttons at the corners of the pattern allow for drainage of wet product; and (4) the CROSSTOP pattern, cleats 3/8″ x 3/8″ taper down to 1/4″; and open 8″ x 8″ pattern allows water drainage and ease of cleaning. All four patterns have a working strength PIW of 100 lbs.

Food Grade FABYSYN Custom Belts – MIPR Corp’s cleat thicknesses of 3/8″ (SD), 1/2″ (MD), 5/8″ (HD), or more, are available on FABSYN 100 or 150 belts in any height from 1/4″ to 3″ (straight or scoop). Cleat centerline available are 4″, 4 3/4″, 6″, 8″, 9″, 12″, 16″, 18″, 24″ and larger. Customer scoop cleats are fabricated with a typical forward pitch of 30°, with heights of 2″ to 2 7/8″. V-Guides in A, B, C or D sections are available. Straight or sloped vanner edges are applied in heights of 1/2″ to 1 1/2″. Belts can be made with prepared ends for field splicing or manufactured endless. Custom cleats are applied to 2-ply FABSYN 100 3/64″ x FS, or 3-ply FABSYN 150 3/64″ x FS. If other fabrics, compounds or splicing methods are required, call 1-800-540-1846.

LACING & SPLICING CONVEYOR BELTING

Selecting the correct lacing option for your belt is critical. MIPR Corp offers a variety of lacing styles and materials to meet the needs of every application.

CUSTOM SPLICING OPTIONS:

Recessed Lace: Mechanical splice area is recessed below the belt surface.

Overflap: Mechanical lacing is installed below the belt surface and the top cover is separated from the belt carcass creating a flap over. The cover can be glued down after installation.

Hidden Lace: Mechanical fasteners are installed below the belt cover to prevent the lace from contacting the product.

Finger Hinge Lace: Finger hinge lace is equipped with flexible, hinged plastic lacing, creating an easy, quick repair alternative to endless belts. FHL requires the belt be made of PVC or polyurethane, have a thickness of .08″ to .263″, have a minimum belt length of 55″, and a maximum belt width of 40″.

Thermoplastic Hinge: Thermoplastic hinge lace is made with the same homogenous material as your belt. This lace is welded to the belt and connect with a metal or nylon pin. Nylon pins should be used when metal detectors are required. (This option is available for Volta products only.)

ENDLESS NON-MECHANICAL SPLICING SOLUTIONS

Endless splicing methods eliminate the need for hardware fasteners. This fabrication technique is excellent for food processing and applications where products need to be handled with greater care.

Step Splice Belt: For belts with multiple plies. Plies are separated and “stepped” to interlock with one another at the splice point. Performed by experts in our fabrication facilities for quality assurance and appropriate curing time.

Skived Splice: A precision grinding technique is used to achieve uniform thickness at the splice point for a variety of applications.

Finger Splice: For thermoplastic, urethane and PVC belts. A very durable splice that maintains a smooth belt surface throughout the splice area. Multiple finger patterns are available to meet a variety of applications and system pulley sizes.

Endless-Prepared: We square and prepare the belt’s ends in our fabrication facilities for hot or cold cement bonding at the customer’s site. (Cement bonding kits with instructions are available.)

Double Finger Splice: Unlike a standard finger splice, fingers are cut from multiple plies, staggered, then fused together by heat and pressure to create a stronger, more flexible splice.

Stitched Reinforcement: Certain applications put unusual wear on splices and edges. These areas can be strengthened with stitching.

Longitudinal Splicing: Very wide belts are created by longitudinally splicing two or more belts of narrower dimension. Plies are expertly stepped and bonded in our fabrication facilities to create a uniformly smooth belt as wide as the application requires. Ultra-wide belts can be made endless prior to shipping… or have ends prepared for field splicing. V-guides and other profiles can also be added.