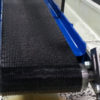

With same-day solutions and emergency shipping, industry-specific insight and over 30 years of experience, MIPR Corp has built a reputation as one of the nation’s leading conveyors manufacturers. We create custom conveyor systems that keep companies moving forward—fast.

Our experienced team of field-savvy engineers work with a wide range of industries, understand all the relevant rules and regulatory requirements, solve site and budget challenges and bring projects in on time and under budget. We use state-of-the-art technologies, work only with the highest quality materials and respond rapidly to all customer needs and requests.

You will find MIPR Corp custom conveyors in airports, agriculture, aggregate and concrete, commercial fishing, construction, food processing, forestry, mining and quarrying, manufacturing and many more high-pressure industrial environments. Our conveyor systems work as hard and as well as they do because we do, too.

To see what MIPR Corp can do for you, bring us your specific conveyor problem or your specifications for a completely custom conveyor system today.

CONVEYOR TERMS:

Angle of Incline – The degree a conveyor is tilted from horizontal.

Drive Pulley – Pulley connected to a power source used to drive conveyor. Usually the drive pulley is the head pulley, but on some kinds of systems, including many package handling conveyors, the drive pulley is located underneath the conveyor.

Gravity Take-up – Device used to remove slack and stretch in a conveyor belt. A free weight is suspended from a pulley on the return side of the belt. The take-up is free to lower as needed to remove any slack as the belt operated. The gravity take-up is usually located as close to the drive pulley as possible.

Head Pulley – Pulley at discharge end of belt. The head pulley is usually powered by conveyor drive source. Pulley “pulls” belt along the conveyor.

Return Idler – Idlers used to support the belt as it passes underneath the conveyor structure.

Roller Bed – Free-wheeling rollers on which the carrying side of the belt rides.

Screw Take-up – Device utilizing a bolt construction used to lengthen the conveyor to remove slack in the conveyor belt. By moving a bolt, the tail pulley is pushed away from the head pulley thus removing slack from the belt.

Slider Bed – A smooth, flat surface (usually steel or wood) beneath the carrying side of the belt.

Snub Idler – Idler used to increase the amount of belt in contact with the pulley or to deflect the belt in a different direction. Snubbing a belt near a pulley can increase the effective tension at the pulley.

Tail Pulley – Pulley at the beginning of the carrying run of the conveyor. The tail pulley is usually free-wheeling.

Troughing Idler – Grouping of idlers on the carrying side of the conveyor deigned to make the conveyor belt curve into a cupped shape, increasing conveyor capacity. Troughing idlers are usually 20°, 35°, or 45°.

Skirtboard Rubber – Skirtboard rubber is primarily used at the loading point to guide product into the center of the belt and to prevent spillage.