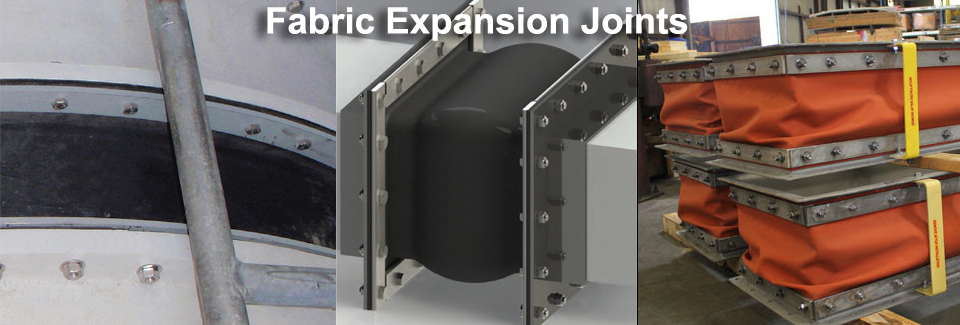

Fabric expansion joints are non-metallic flue duct expansion joints that provide stress relief for piping and ducting systems by absorbing thermal growth and shock, isolating mechanical vibration, and allowing for misalignments. We are a leading supplier of fabric expansion joints engineered to handle low-pressure (±3 psig) industrial applications including coal-fired power generation, gas turbine, marine, cement, incineration, nuclear, pulp & paper, refining, electrochemical with temperatures ranging from -100°F to more than 2000°F.

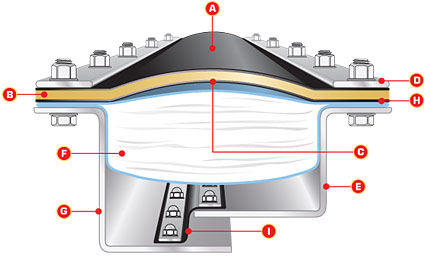

Flexible Element Components

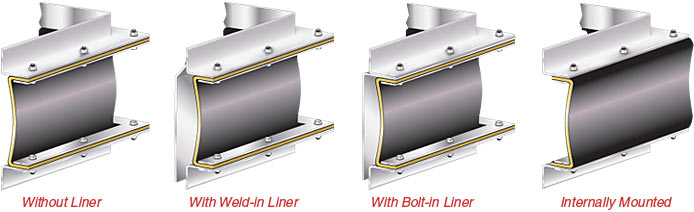

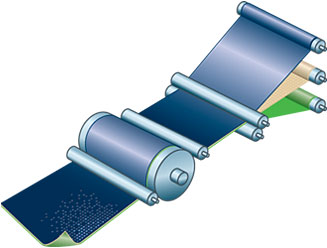

The flexible element is the most active component of the expansion joint. It contains the gas seal and must be 100% non-permeable, and allow movement in all directions. The flexible element’s Structural Gas Ply must also be designed to withstand the system temperature and pressure and be chemically compatible. The Flexible Element may also include additional thermal barriers, as well as retaining and reinforcing plies. MIPR Corp offers flexible elements in both Flat Belt and U-Shaped “Integrally Flanged” varieties, and when combined with additional thermal layers and insulation pillows, are suitable for temperatures up to 2000°F.

The flexible element is the most active component of the expansion joint. It contains the gas seal and must be 100% non-permeable, and allow movement in all directions. The flexible element’s Structural Gas Ply must also be designed to withstand the system temperature and pressure and be chemically compatible. The Flexible Element may also include additional thermal barriers, as well as retaining and reinforcing plies. MIPR Corp offers flexible elements in both Flat Belt and U-Shaped “Integrally Flanged” varieties, and when combined with additional thermal layers and insulation pillows, are suitable for temperatures up to 2000°F.