MIPR Corp will solve your light to medium duty conveyor belting challenges from package handling to raw material processing applications including special surfaces for package handling, belts that are grease and oil resistant, non-marking, and static conductive belts.

MIPR Corp carries a wide variety of thermoplastic belts for the various material-handling needs of the printing and paper processing industries, including paper roll transferring, sheeters, folders, and stackers. You will find our staff extremely knowledgeable with more than 30 years of experience in conveyor belting applications.

Contact MIPR Corp today to discuss your needs for light to medium conveyor belting for your application. We carry a full-line of conveyor belts and belting.

LIGHTWEIGHT BELTING & CUSTOM FABRICATIONS

MIPR Corp is continually adding new products and expanding our capabilities to help you create the products you need. Our fabrications demonstrate our capabilities to utilize new technology, modern equipment, and cutting-edge techniques. The outstanding quality of this workmanship relates directly to the solid experience and training of our belt fabricators. We offer all standard fabrications plus several of our own specialties.

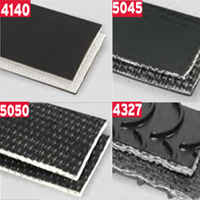

Custom Covers & Specialty Belting

Designing equipment to perform in challenging environments calls for belt coverings that are up to the task.

Specialty and Covered Products

MIPR Corp offers custom coverings for flat belt, V-belts, and timing belts including urethane, steel/Kevlar reinforced, neoprene, rubber, and HTD. Products like these are highly effective in a variety of applications from vacuum systems, to orienting and pulling products down the line.

Urethane Foam Covering

MIPR Corp’s green, urethane foam is created to coat and back flat belts, timing belts and V-profiles. Features include:

- Belt surface with high grip properties

- Excellent abrasion resistance

- Soft, yet durable coating

- Non-marking to the items being conveyed

Because the coating is made of urethane, we can heat-weld this product to the base belt and help you sidestep the higher production coast of chemical bonding.

Power Turn Belts

MIPR Corp fabricates three types of power turn replacement belts: chain driven, urethane guide bead, a guide wheel or bearing drive. Furnished complete with specified drive hardware and special attachments (chains, grommets, bushings, rivets, etc.)

The most common type of power turn belts (chain driven) are frequently used in airline baggage and package handling applications. They are also used in distribution centers, newspaper plants, industrial manufacturing, paper mills and food processing plants, to name a few.

Normal power turn belt applications are 45°, 90° and 180°; however, any belt for spiral lifts of 15° to 720° can be fabricated.