Metal Mesh Belts

FIND ANY METAL MESH BELT YOU WANT - SAMPLE REQUESTS & SPECIFICATION SHEETS SENT OUT SAME DAY!

- MIPR Corp Belt Types

- MIPR Corp Belt Material Information

DURAFLEX

DURAFLEX is MIPR Corp’s newest metal belt. It’s the most open metal belt available that does not compromise belt strength, can be easily retrofitted and is easy to splice.

Splices in as little as 30 seconds – Our unique splice design (patent pending) can be easily spliced from the side of the unit, without weaving, using our Kwik connect Splice Rod. The splice is a strong as the rest of the belt, so there is no weak point to fail. No special tools are needed and welding is not required!

Longer belt life – Reduce belt weight means less energy is consumed by the belt and reduced wear on units without compromising strength. Unlike other light duty conveyor belts, DURAFLEX truly hinges, thereby reducing belt fatigue and providing increased belt life.

Easy to clean – DURAFLEX is made from food-safe stainless steel with unobstructed openings that allow for easy cleaning. versions standards are also available.

Increased carrying capacity – Handles heavier loads than typical light-duty conveyor belts due to the unique drive sprocket opening (patent pending), which add increased strength.

Allows for tight transfers – Small diameter drive rolls or sprockets allow you to achieve an extremely tight transfer, reducing product damage and the loss of even small delicate products.

DURAFLEX belts are manufactured from durable, food-safe stainless steel. They are available in 3/8″ and 1/2″ pitches, and in widths from 4 to 144 inches.

The most common applications where DURAFLEX belts are used include:

Cooling, Washing, Coating, Baking, Frying, General product transfer, Breading, Battering.

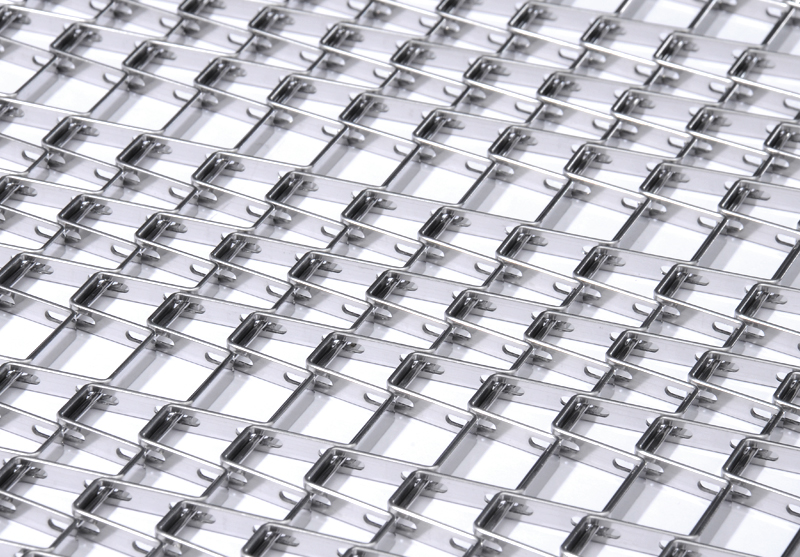

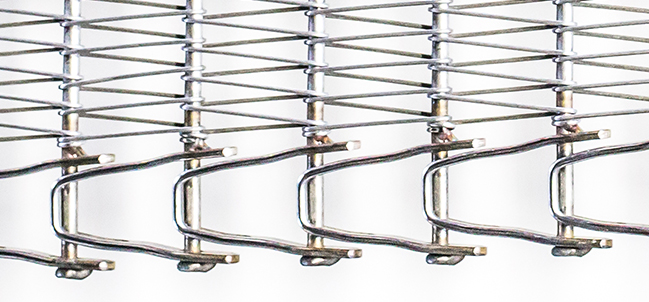

Cam-Grid Xtra Spiral System

Available in a rod-only construction or with a variety of mesh overlays, Cam-Grid Xtra spiral system belting is tougher, stronger, faster and able to carry heavier loads than any belt in the traditional Cam-Grid product line. Yet, gentle handling of fragile products is not scarified. With a longer belt service life, greater load-carrying capacity and fewer required belt repairs than traditional Cam-Grid or competitor’s grid style belts. Cam-Grid Xtra is the better value.

Trouble-free operation in tough applications – Designed for superior strength, Cam-Grid Xtra is made with .225″ diameter high tensile rods that are 35% more deflection-resistant than the rods in competitor’s belts…as well as super heavy duty links that are more than twice as heavy as our standard heavy duty links.

Carries more product without extra belt weight – Weighing less than Heavy Duty Cam-Grid and up to 30% less than Cambri-Link’ belting, Cam-Grid Xtra carries more product without sacrificing belt life.

Maximizes product throughput in tight spaces – An extra-flexible belt, Cam-Grid Xtra incorporates links that allow the belt to travel with a 1.6:1 turn ratio, making it ideal for smaller-radius spiral cage systems.

Wears evenly for extra-long service life – All Cam-Grid Xtra belts can be flipped – the only 1.6:1 turn radius belt with this feature – meaning that these belts wear more evenly and provide maximum service life.

Outlast competitors’ belts and saves you money – Made with super heavy duty links and .225″ diameter rods, Cam-Grid Xtra belts are designed to wear better, handle more tension, require fewer repairs, and last longer than competitors’ belts.

Another aspect of our superior construction is the use of spring temper stainless steel mesh overlays. Advantages include:

- Exceptionally smooth, flat mesh surfaces offer uniform product support with minimal product marking.

- Resistance to deformation when products that are frozen to the belt are forcibly removed.

- Extreme resistance to fatigue and damage results in a long, trouble-free belt life.

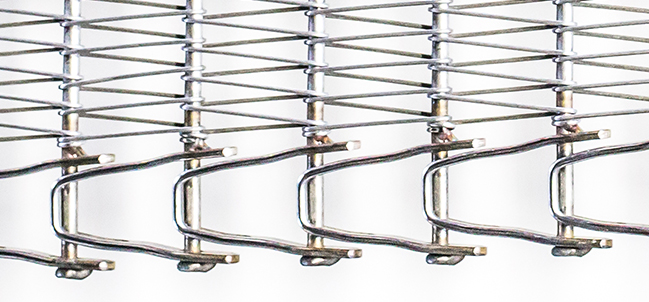

Cam-Grid Belts

Cam-Grid belts are our most popular application – adaptable spiral system belts. They’ve proven themselves in spiral system applications throughout the world, running smoothly and dependably year after year.

With their positive sprocket drive, Cam-Grid belts provide a smooth, continuous product flow that is gentle with fragile or delicate products. They save money by protecting product quality and reducing waste.

Fully collapsible for easy cleaning, Cam-Grid belts are available in standard (2.2) radius, reduced (1.7) radius and tight (1.1) radius designs. It can be manufactured with a double pitch overlay, or with plastic filler rods or strips for supporting extremely small products.

Rods-Only Construction – A rods-only construction provides maximum air circulation, making these Cam-Grid belts ideal for cooking, proofing and freezing of baked goods. They are also suitable for other applications such as freezing of larger cuts of meat and poultry, and products in trays or packages where minimal product support is required.

Mesh Overlay – When product support or smaller openings are needed, a balanced weave mesh overlay is added. Flexibility is maintained, while adapting the Cam-Grid belt for a particular application such as freezing soft dough products, beef patties, fish sticks, and other prepared products.

Standard Radius Belts – The turning radius of a Cam-Grid belt is determined by the ability of the links to nest on the inside edge of the turn and by the width of the belt. Since the slot length determines the amount of nesting and is a fixed dimension, the minimum turning radius becomes a factor of belt width. For a standard radius Cam-Grid belt, the nominal inside belt radius is 2.2 x the belt width.

Tight Radius Belts – Cam-Grid tight radius belts are configured with an internal row of 3/4″ pitch heavy-duty non-collapsing links which carry the drive tension through the turn. This row of links, located based on turn radius, provides two belt lanes of equal width while allowing a tight turning radius of 1.1 x the belt width.

The tension-bearing inner links can be moved to adjust the belt turning radius; however, Cam-Grid tight radius belts should operate only with a radius appropriate to the belt width and central diver link location.

The inner edge of the Cam-Grid tight radius belt is the standard 3/4″ pitch link, while a 1″ pitch link is used on the outer edge to allow for additional extension.

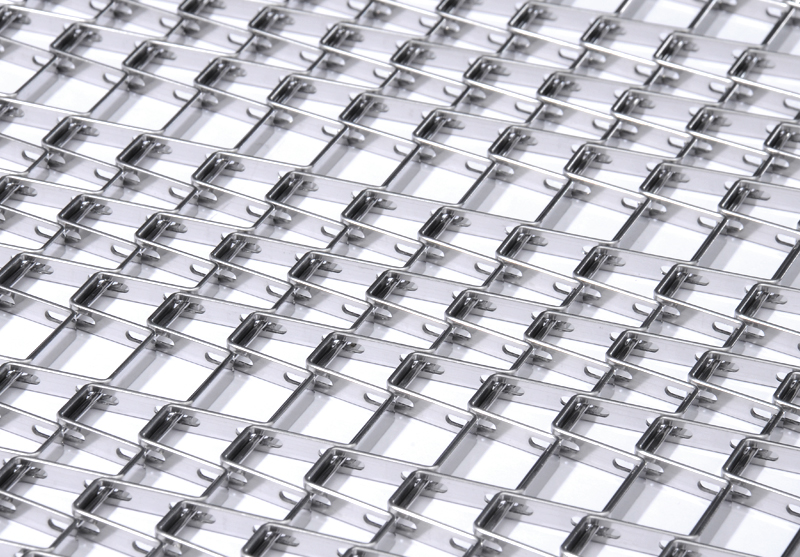

Precision Belts and Sprockets

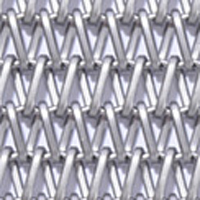

For hard-to-track and difficult-to-drive conveyors, or for those that are prone to belt distortion and short belt life, we offer MTS Sprockets. MTRplus Drive Rollers, and their precisely-matched companion meshes. The system is simple, and ensures conveyors will operate without constant cleaning, tracking adjustment, or replacing. The following systems are all positive drive combinations designed to provide you with trouble-free operation. Don’t be fooled by imposters! Only MIPR Corp offers the original, most precise belts, sprockets and drive rolls.

MTS Sprockets and Mesh Belt System – MTS system features belts matched precisely with machined tooth sprockets. The unique design of the machined teeth provides self-cleaning action necessary in many applications where product consistencies are thick or tend to bind. Additionally, numerous custom options are available. These include the widest range of diameters available in the industry, idle end “guide” sprockets, custom face widths, cleaning grooves for additional product buildup prevention, and many others.

Many standard and customized mesh combinations are available for short to long process conveyors, as well as for transfer conveyors. Precision Belts utilize our balanced Flat Seat technology which reduces vibration, improves product support and dramatically reduces belt stretch. Even better, many of the mesh designs are very flexible, and nosebar diameters are small as 1/4″ are possible.

Once the conveyor is aligned and started, the MTS Sprockets provide a reliable and consistent positive drive. This positive drive also maintains the belt position during operation. No other steering or tracking method is needed. The parallelogram-shaped teeth precisely match the shape of the belt opening to ensure slip-free and trouble-free operation.

MTRplus Drive Roll and Mesh Belt System – There has never been a positive drive roll like the MTRplus. Using machinery specifically designed to produce these rolls, tooth profiles and tooth locations match the corresponding mesh belt perfectly – each and every time. The MTRplus thrives in those applications where heavy loads and high temperatures are the norm. Like our MTS Sprockets, a wide array of custom options are available to allow the MTRplus roller to provide the best possible performance for your conveyor system.

The individual teeth of the roll are machined to allow for expansion and contraction of the belt during startup, normal operation and cool-down, ensuring proper functionality throughout the entire production day.

FFR Mesh – For applications where a lighter-weight belt is required, or where a straight-through clear opening is important, the FFR series of Precision Belts is the answer. This series offers all of the benefits of the standard Precision Mesh Belt, but the percentage of open area is increased to further enhance clean-ability and mass reduction.

MIPR Corp will solve your metal mesh conveyor belting problems.

MIPR Corp are experts in applying our knowledge of metal mesh belts to applications involving baking and industrial transport, flow through the belt and higher to lower temperatures.

MIPR Corp carries a large selection of application specific metal mesh belts. View the brochures listed below, then call us—you will find knowledgeable staff with 30 years experience in metal mesh belting.